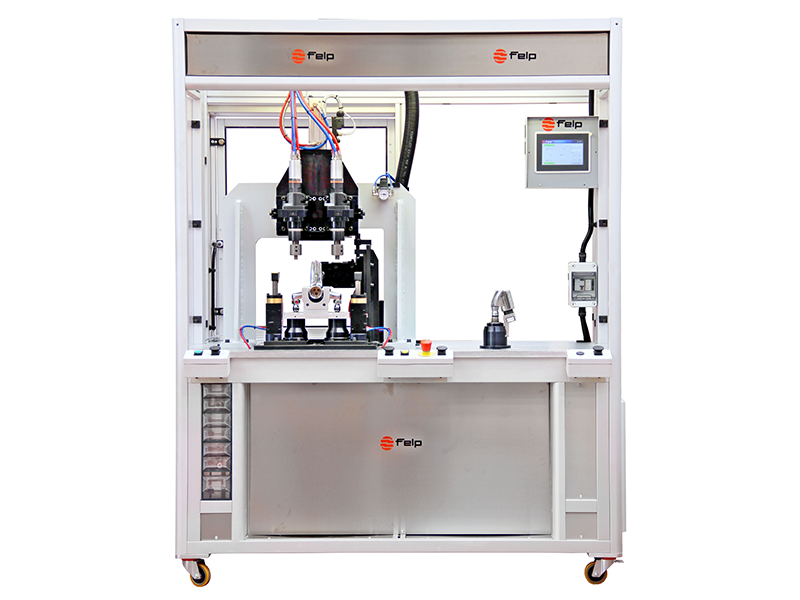

At FELP, we develop machinery and automated assembly lines capable of handling a wide variety of products and components. Our technological solutions are designed to adapt to the needs of various industrial sectors, ensuring efficiency, precision, and flexibility.

One of FELP’s key strengths is the in-house management of the entire machinery manufacturing process, which allows us to offer a high degree of responsiveness and adaptability to customer requests. This vertical integration allows us to reduce development times, respond quickly to customizations, and ensure constant quality control at every stage of the project.

We create custom systems for the production and assembly of:

Valves, Pneumatic and hydraulic fittings, Medical devices, Electromechanical components.

Whether small batches or high-volume production, FELP is the ideal partner for automating processes and optimizing productivity in a reliable and innovative way.